Gas Analysis

What happens if gas levels in your industrial process change without you realising it? How does it affect safety, efficiency and environmental compliance? Gas analysis is crucial in several industries, from chemical and petrochemical to water and wastewater, food production, pharmaceutical, energy production and pulp & paper. At OmniProcess, we offer advanced solutions that ensure reliable measurement results and optimise process control.

- System Solutions

- Gas Analysis

- Liquid Analysis

- Flowmeters

- Pressure Gauges

- Level Gauges

- Temperature Gauges

- Laboratory Analysis

- Data Loggers

- Regulators

More information

What is gas analysis and why is it important?

Gas analysis involves the measurement and identification of gases in a particular environment or process. The purpose may be to ensure product quality, improve energy efficiency, fulfil environmental requirements or protect personnel and equipment. Accurate measurements are essential to make informed decisions and prevent potential risks.

Our solutions in gas analysis

OmniProcess offers a comprehensive range of gas analysers and systems, adapted for demanding industrial environments. Our solutions include:

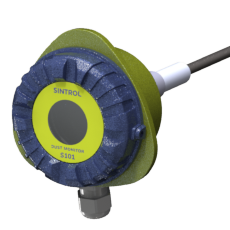

In-situ gas analysis

In-situ gas analysis enables continuous measurement of gases directly in the process without the need for sample preparation. This provides fast and accurate analysis, making it possible to optimise operating conditions and ensure compliance with environmental requirements.

Applications for in-situ gas analysis

- Combustion control - Optimising fuel consumption for higher efficiency and reduced emissions.

- Emissions monitoring - Continuous monitoring of emission levels to fulfil environmental rules and legal requirements.

- Process optimisation - Accurate monitoring of gas levels to improve industrial processes and reduce energy consumption.

Gases we can analyse:

- Ammonia (NH₃)

- Biogas (Methane, CH₄)

- Carbon dioxide (CO₂)

- Carbon monoxide (CO)

- Acid (O₂)

- Water (H₂O)

With our in-situ gas analysis, you can get fast and accurate readings, leading to increased control, better efficiency and reduced environmental impact.

Extractive analysers

Active analysers with extractive systems are used to analyse gases under controlled conditions outside the process. By extracting gas samples, these systems enable accurate and customisable analysis, making them ideal for complex industrial environments.

Applications of extractive gas analysis:

- Power plants and petrochemical industry - Continuous monitoring of emissions, including NOx, SO₂ and CO₂, to meet environmental requirements and optimise combustion.

- Production facilities - Ensures optimal operation and product quality through accurate gas analysis in manufacturing processes.

- Environmental and labour monitoring - Provides accurate data for regulatory requirements and improved working environment.

Gases we can analyse:

- Hydrocarbons (HC)

- Chlorine (Cl₂, ClO)

- Carbon dioxide (CO₂)

- Carbon monoxide (CO)

- Nitrogen oxides (NO₂, NO₃, NOx)

- Ozone (O₃)

- Sulphur oxides (SOx)

- Acid (O₂)

GC/MS/FTIR

OmniProcess offers a range of advanced analytical instruments for detailed gas detection in laboratory and industrial applications.

Prima PRO Process Mass Spectrometer is designed to maximise product yield and increase profitability through fast and accurate online gas analysis. With an analysis cycle of 1 to 20 seconds per point, it can efficiently track process dynamics and deliver comprehensive data to process control models. It has a stable design with automated calibration intervals of 30 to 90 days and an availability above 99.7%. Its compact size and enhanced connectivity make it ideal for demanding industrial environments.

MAX-iR FTIR Gas Analyser combines FTIR technology with StarBoost Enhanced Optical Technology, enabling the detection of gases down to single-digit ppb levels. With integrated temperature and pressure sensors as well as vibration damping, it provides accurate and stable measurements in demanding certification applications.

GC8000 is a gas chromatograph specifically developed for the oil, gas and petrochemical industries. Its modular design enables parallel chromatography, increasing the speed and flexibility of analysis. With a user-friendly 12-inch colour touchscreen and AI-based maintenance support (GCAI), it simplifies operation and reduces the risk of downtime.

Why choose OmniProcess for gas analysis?

With over 30 years of experience and partnerships with world-leading suppliers, we offer:

- Customised solutions - customised to industrial needs.

- High quality technology - from the most trusted brands on the market.

- Support and services - expertise throughout the product lifecycle.

Request a quote today

Need guidance in choosing a gas analysis solution? Our experts will help you find the right one. Request a quote today and discover how we can optimise your process with accurate and reliable gas analysis.