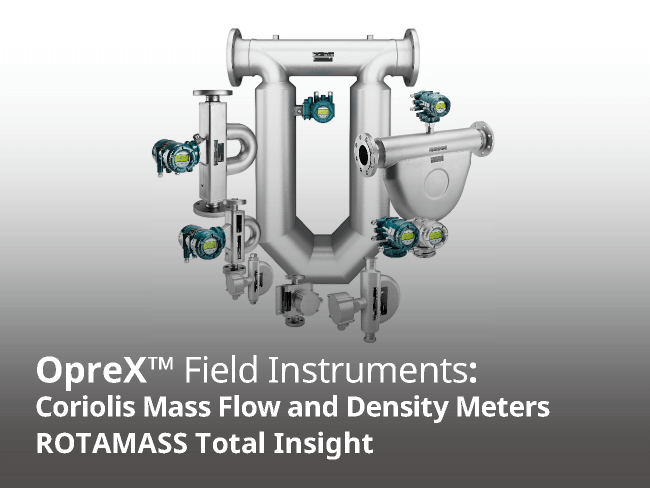

ROTAMASS Total Insight is Yokogawa's range of Coriolis mass flowmeters, developed to deliver high accuracy and robust performance. The series consists of six dedicated product lines covering a wide range of applications, from low flow and hygienic processes to demanding industrial environments and high pressure applications. With advanced diagnostics, on-demand features and support for modern communication protocols such as Ethernet-APL, ROTAMASS Total Insight is ready to meet the demands of the future.

Product lines in the ROTAMASS Total Insight range

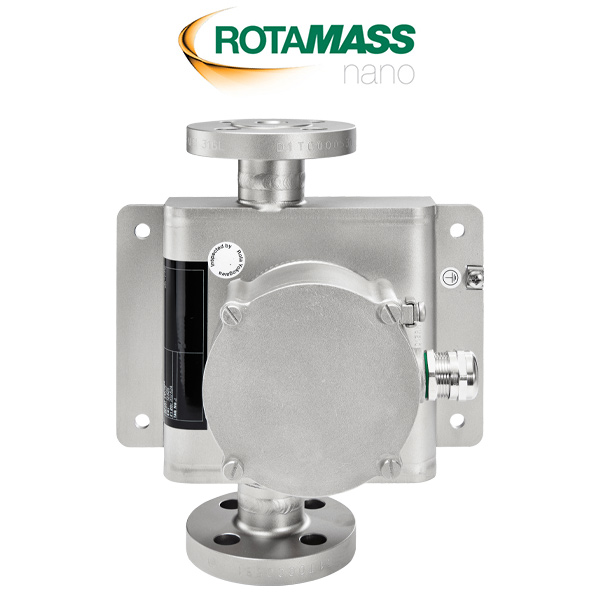

ROTAMASS Nano - When every drop counts

ROTAMASS Nano is designed for extremely low flow rates and offers high precision for small volumes. Its double curved tubes compensate for density and temperature variations, providing stable and repeatable measurements.

Typical applications:

- Chemical dosing

- Low flow measurement of liquids and gases

- Precision coating

- Research and development

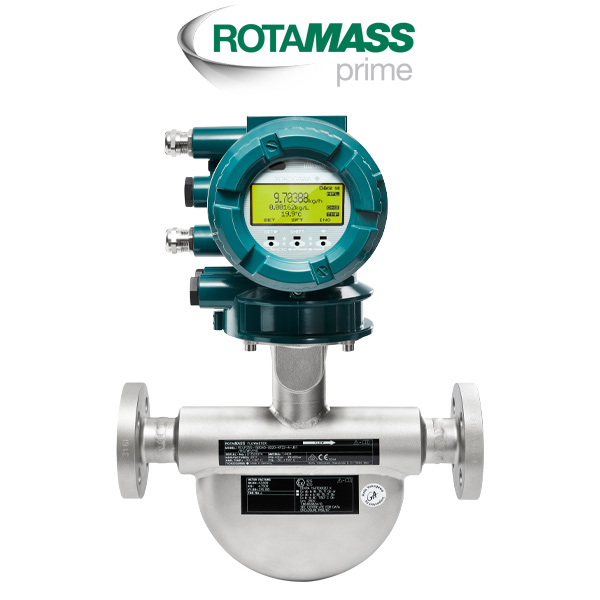

ROTAMASS Prime - Versatility in applications

ROTAMASS Prime is a flexible solution for standard applications, with the lowest pressure drop and high turndown on the market. It can be customised for customer-specific needs, including in-line concentration and density measurement.

Typical applications:

- Batching and blending

- Mass balances

- Catalyser feed

- Filling and dosing

ROTAMASS Hygienic - For hygienic processes

ROTAMASS Hygienic is certified to EHEDG and 3A standards, making it ideal for the food, beverage and pharmaceutical industries. The design ensures continuous product quality and minimal wastage.

Typical applications:

- Fermentation

- Measurement of colostrum and juice

- Online concentration measurement of sugar

ROTAMASS Supreme - Innovation meets experience

ROTAMASS Supreme delivers high performance for demanding applications, including advanced diagnostics and superior handling of air bubbles in liquids.

Typical applications:

- Combustion control

- Material balances

- Gas bubble management

- Process control

ROTAMASS Intense - Safety at high pressure

Designed for high-pressure environments, ROTAMASS Intense offers maximum safety and accuracy for liquids and gases.

Typical applications:

- Natural gas injection

- Compressed gases

- Refinery processes

- Offshore and onshore applications

ROTAMASS Giga - Big on performance

ROTAMASS Giga is ideal for high-flow applications and offers superior accuracy even at low flow rates. With a robust design and long service life, it is ideal for large processes.

Typical applications:

- LNG distribution

- Loading of ships and trains

- Bitumen and tar

- Cementation and hydrofracturing

Features and benefits

- High accuracy: ±0.1 % for liquids and ±0.35 % for gases.

- Robust design: Made with durable materials like stainless steel and Alloy C-22.

- Advanced diagnostics: Total Health Check and Tube Health Check for continuous monitoring.

- Flexible communication: Ethernet-APL, HART, Modbus RTU and more.

- Wide temperature range: From -196 °C to +350 °C depending on the model.

- Hygienic design: Certified to EHEDG and 3A standards.

Applications

- Chemical industry -> Catalyst feed, mass balance, process control.

- Food and drink -> Fermentation, bottling, online concentration.

- Oil and gas -> LNG distribution, refining, high pressure measurements.

- Pharma and biotechnology -> Bioreactors, pharmaceutical manufacturing.

- Energy and power plants -> Combustion control, cooling water monitoring.