Installation

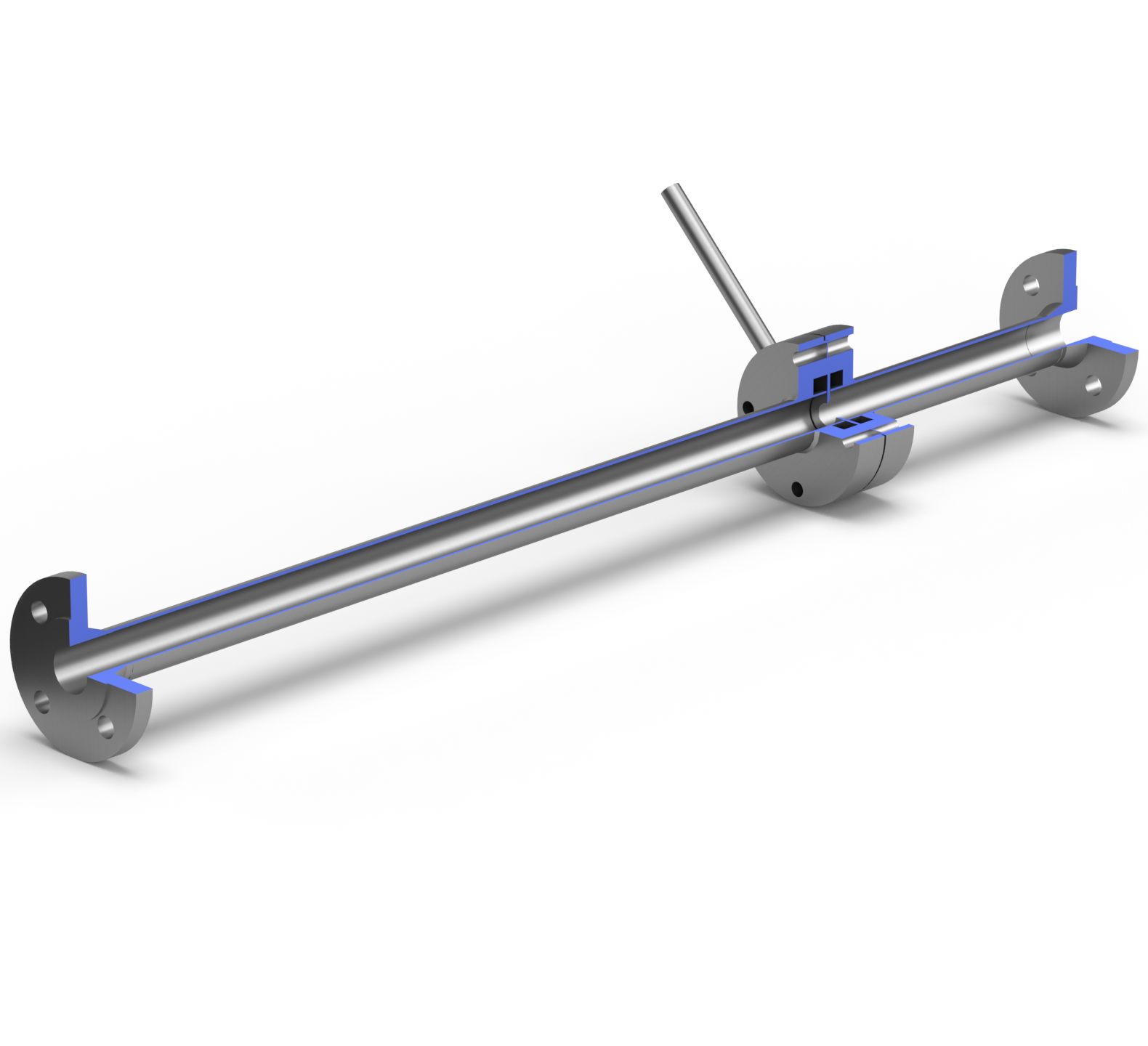

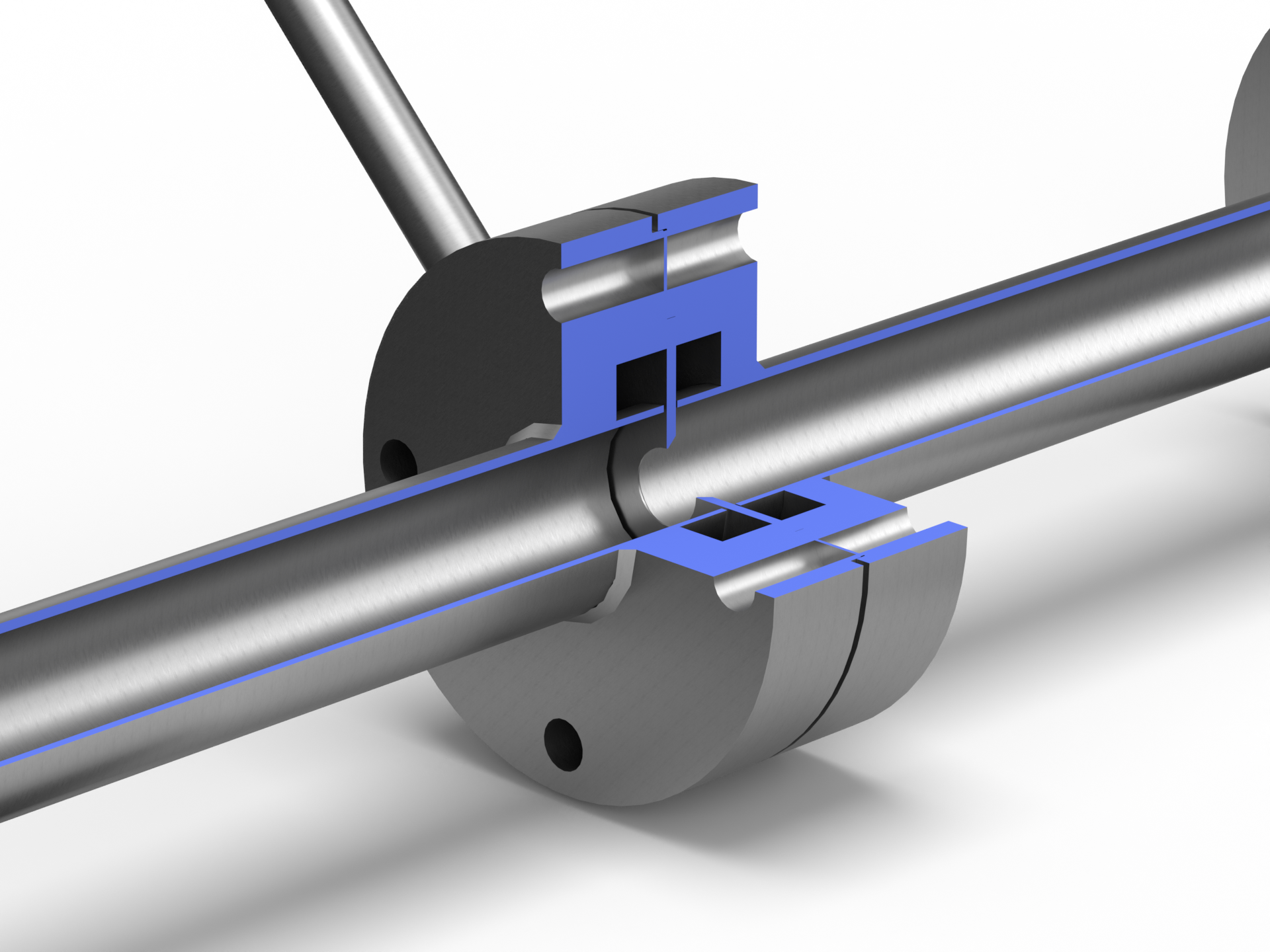

Before installation, the groove ring must be kept clean and protected against corrosion and physical damage. It is also important to pay close attention to the sharp edge of the groove ring. Once it is ensured that the ring is clean, install it carefully so that the hole of the groove ring is centred with the centre of the pipeline. The location of the pressure tappings varies depending on whether the ring is used for liquid, gas or vapour. It is not supplied with any safety devices and must not be used at pressures higher than those indicated on the nameplate. The pipework must therefore be fitted with a safety device. However, this type of primary element requires no special maintenance.

Size

|

DN

|

Inches

|

Total length (mm)

|

|---|---|---|

|

10

|

3/8"

|

400

|

|

15

|

½"

|

550

|

|

20

|

¾"

|

700

|

|

25

|

1"

|

900

|

|

32

|

1 ¼"

|

1100

|

|

40

|

1 ½"

|

1300

|

|

50

|

2"

|

1500

|