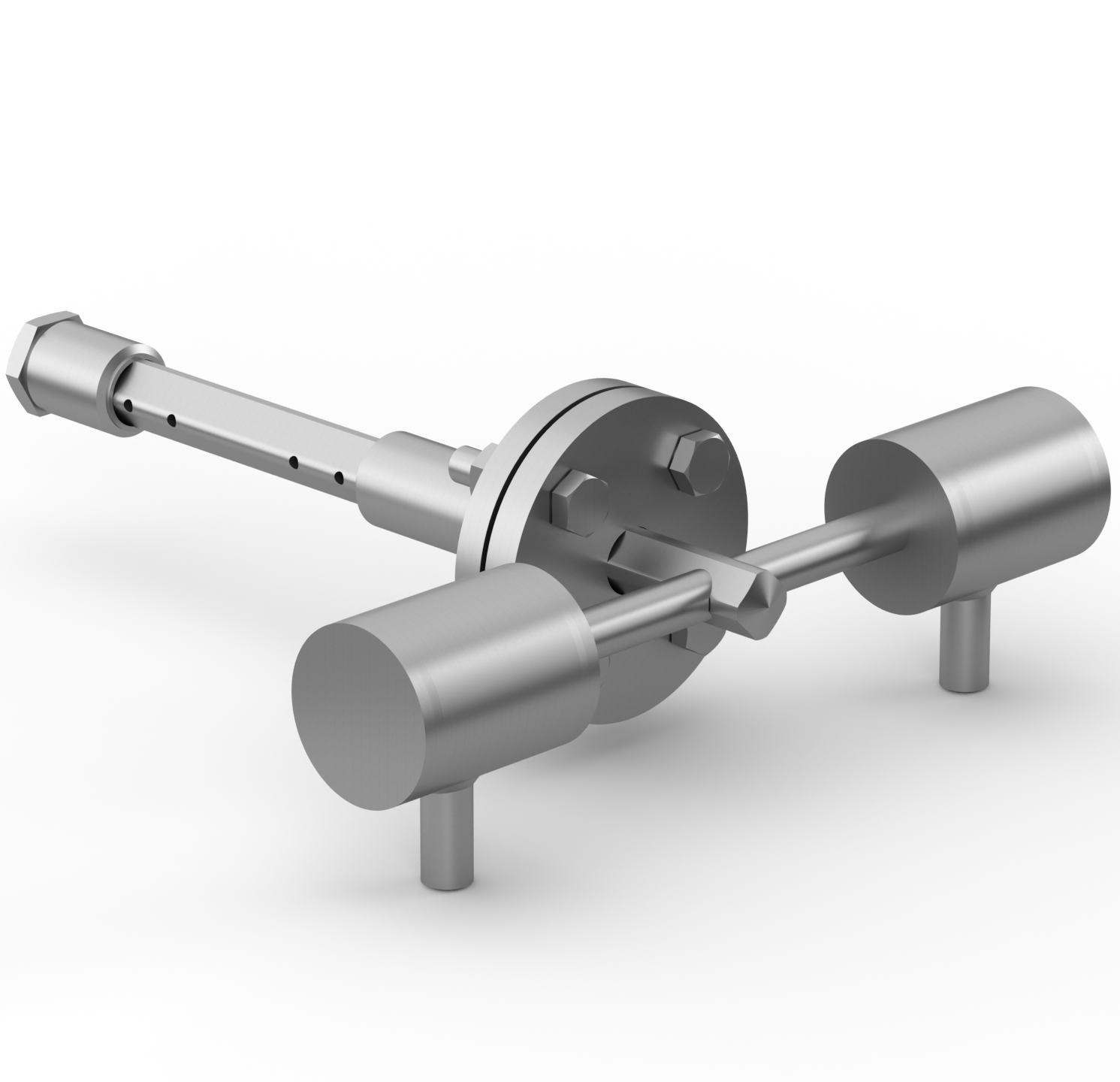

Design

The PITOBAR Averaging Pitot Tube is constructed with a diamond-shaped beam and multiple ports that are positioned centrally within concentric rings of equal area, facing the upstream side. This is done to get the best averaging of the dynamic pressure, resulting in a more accurate flow reading. The pitot tube creates a differential pressure signal proportional to the flow rate: Differential pressure = (Pstatic + Pdynamic) - Pstatic.

Installation

For optimum installation, the pitot tube should be placed in a straight cylindrical tube with a uniform cross-sectional area and free of obstructions. The internal pipe diameter must not deviate by more than 0.3 % to ensure accurate differential pressure calculations. To ensure accurate measurements, the use of full flow valves upstream of the primary element is recommended. The roughness of the inner pipe wall should fulfil specific limits depending on the material used. In case of vapour flow, horizontal mounting with a slope of 5 degrees is recommended to facilitate condensate flow. Purge connections are available for liquids with contaminants, and regular maintenance is recommended to maintain accurate readings. For proper instrument connection, the differential pressure transmitter should be placed below the pitot tube for liquid and vapour flow and above it for gas flow, with impulse lines inclined to allow air discharge.

Requirements for straight pipe lengths

Certain installation requirements for straight pipelines must be met to achieve the most accurate flow measurement. See the table below.

|

Upstream (x D)

|

Downstream (x D)

|

|

|---|---|---|

|

Single 90° bend

|

9

|

3

|

|

Two or more 90° bends in the same plane

|

14

|

3

|

|

Two or more 90° bends in in different planes

|

24

|

4

|

Maximum authorised differential pressure

Without bottom support, with reference to mechanical bending. Pressure is measured in bar. See table below.

|

Length

|

DK200 @ 20°C

|

DK200 @ 400°C

|

DK250 @ 20°C

|

DK250 @ 400°C

|

|---|---|---|---|---|

|

200

|

3,75

|

1,81

|

||

|

300

|

1,66

|

0,81

|

2,52

|

1,19

|

|

400

|

0,94

|

0,45

|

1,42

|

0,67

|

|

500

|

0,60

|

0,29

|

0,91

|

0,43

|

|

600

|

0,42

|

0,20

|

0,63

|

0,30

|

|

700

|

0,31

|

0,15

|

0,46

|

0,22

|

|

800

|

0,23

|

0,11

|

0,35

|

0,17

|

|

1000

|

0,15

|

0,07

|

0,23

|

0,11

|