The machined Venturi tube must be installed in a straight cylindrical tube without obstructions and with specific requirements on the inner diameter of the tube. The required straight lengths vary depending on the beta values and the presence of bends or reducers. Full flow valves are recommended upstream, and the inner wall of the pipe must be clean and smooth. The venturi should be carefully centred and connected to the differential pressure transmitter below it for most applications, except for gas flow. Safety devices must be provided to prevent overpressure, and elevated temperatures should be avoided. Regular maintenance means ensuring a deposit-free inner surface. Compliance with ISO 5167 and other standards is essential for quality assurance.

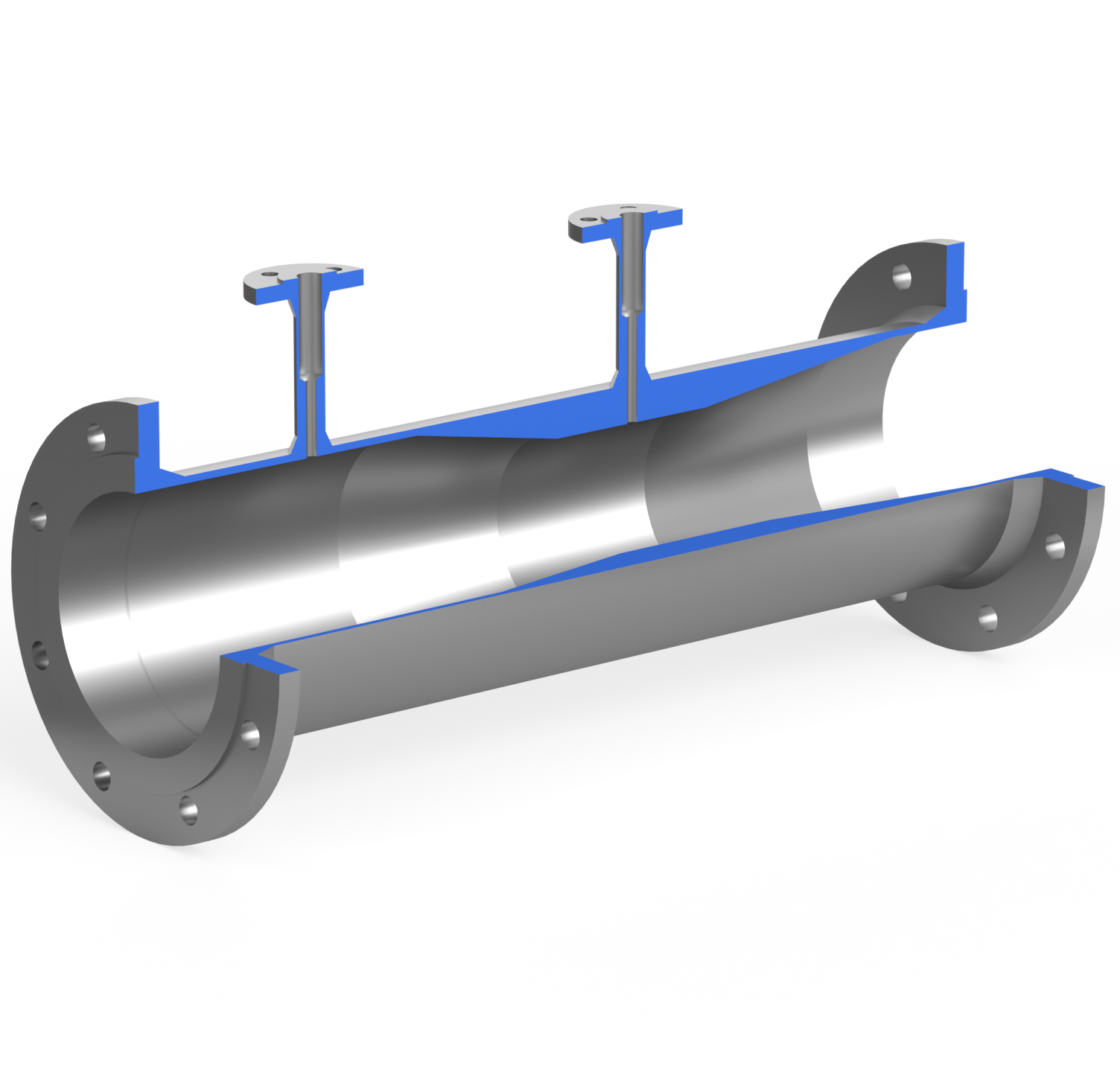

Venturi tube M-cone EMCO Classic

Description of the programme

The classic Venturi tube is one of the most tested and reliable flowmeters on the market. Based on the ISO 5167-4 standard, it offers durable flow measurement with minimal pressure drop.

Characteristics

- Quick and safe installation

- Simple construction

Produktspecifikation

Produktspecifikation Venturirör M-kona EMCO Klassisk

Installationsguide

Installationsguide Pitotrör för större rördimensioner

| Design and calculation standards | ISO 5167-4, ASME MFC-3M |

|---|---|

| Sizes | DN 50 - DN 250, 2" - 10" |

| Material | Carbon steel, AISI 316, Duplex, 254 SMO, other materials on request |

| Mounting style | Weld ends according to DN 2559 or ANSI B16.25. Flanges according to DIN or ANSI B16.5 standards (Greyloc Clamp connection available on request) |

| Pressure connections | Weld ends Ø 21.3 mm, 26.9 mm, threaded connection 3/8", 1/2" BSP, 1/2" NPT or flanged |

| Taps | Single pressure tapping or 2×4 tappings, each arranged with an external ring to equalise pressure |

| Outlet cone | 7-15° |

| Accuracy | 1 % (according to ISO 5167) |

| Pressure drop | Depending on the outlet cone, between 10-15% of the measured differential pressure |

| Limits of Reynolds numbers | 210^5 < ReD < 210^6 according to ASME |

| Shut-off valves | Steam flow condensing chamber |