Flowmeters

From monitoring and controlling liquids and gases to optimising production and resource use, flow measurement is a key part of many industrial processes. With advanced technologies that combine precision, reliability and adaptability, our flowmeters can be used in a wide range of applications, including energy, water and wastewater, chemical production and the food industry. Our wide range of flowmeters ensures that every process receives a solution perfectly tailored to specific requirements and conditions.

- System Solutions

- Gas Analysis

- Liquid Analysis

- Flowmeters

- Pressure Gauges

- Level meters

- Temperature Gauges

- Laboratory Analysis

- Data Loggers

- Regulators

-

Mass flowmeters | Mass flow controllers3 Products

-

Flow Indicator2 Products

-

Differential pressure gauge | DP flow17 Products

-

Calibration equipment1 Product

-

Inductive flowmeters | Magnetic flowmeters | Mag tubes2 Products

-

Variable area flowmeters | Rotameters4 Products

-

Thermal flowmeters10 Products

-

Ultrasonic Flowmeters8 Products

-

Vortex Flowmeter1 Product

More information

Coriolis Mass Flowmeter

Coriolis mass flowmeters are ideal for measuring the mass flow of both liquids and gases with high accuracy. The technology is based on analysing the movement of the liquid in oscillating tubes, providing reliable results even at varying densities and viscosities. OmniProcess works with leading manufacturers such as Yokogawa, whose Rotamass Total Insight series offers precision and flexibility for a range of applications, from chemical handling to food production.

Ultrasonic flowmeters

Ultrasonic flowmeters use sound waves to measure the flow of liquids and gases without disturbing the flow. These meters are ideal for hygienic applications and systems that require minimal maintenance. OmniProcess offers portable models such as the KATflow 200 and fixed installations such as the KATflow 100, which are popular in the water and wastewater management and energy industries.

Magnetic flowmeter | Mag-tube

Magnetic flowmeters, or Mag tubes, are excellent for measuring flow in conductive liquids with high precision. These meters utilise Faraday's law to deliver reliable results even in harsh environments. They are widely used in water treatment, food production and the chemical industry, where their minimal maintenance requirements and long service life are appreciated.

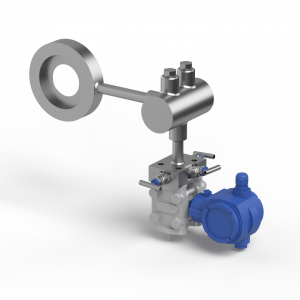

Differential pressure flowmeter

Differential pressure flowmeter is based on using pressure differences across a flow restrictor to calculate the flow. These meters are robust and flexible, making them ideal for demanding applications such as steam and gas in power plants and refineries.

Vortex Flowmeter

Vortex Flowmeter Vortex flowmeters utilise the von Kármán effect to measure the flow of liquids and gases. This technology is particularly useful in applications such as steam, gases and liquids with or without conductivity, high temperature applications in industrial processes such as pulp & paper, food production and energy.

Variable area flowmeter | Rotameter

Variable area flowmeter | Rotameter are simple and reliable flowmeters that use a vertical tube and a float to indicate flow visually. These meters are ideal for laboratories and simple industrial processes where intuitive measurement is important.

Thermal flow meters and mass flow controllers

Thermal flowmeters measure flow by analysing the heat transfer in gas or liquid. They are optimal for low flow rates and are often combined with a flow valve in the same instrument (MFC, mass flow controller) for both measuring and controlling the flow in the process. Used in applications where accurate measurement and/or control of small flows is essential.

Why choose OmniProcess?

OmniProcess combines deep technical expertise with a wide range of flowmeters to meet the unique needs of process industries and laboratory environments. By offering tailored solutions and high-quality products, they help their customers optimise operations, reduce costs and increase the precision of their measurement processes.

Contact us

Need help finding the right flow meter for your application? Contact OmniProcess today for a free consultation or quote. Their experts will help you find a solution that fits your needs and improves your processes.

Frequently asked questions about flowmeters

What is a flow meter and where is it used?

A flow meter measures the flow of liquids or gases for monitoring, control and optimisation. Common applications are in the energy, water & wastewater, chemical and food industries.

What types of flowmeters are available and when are they suitable?

Coriolis (high accuracy, mass flow), ultrasonic (non-intrusive, hygienic), magnetic/mag tube (conductive liquids), differential pressure/DP (robust for vapour/gas), vortex (vapour/high temp), float (simple visual indication) and thermal (low gas flows).

What are the benefits of OmniProcess solutions?

A wide range from leading manufacturers, customised choices for process and lab, and support throughout the lifecycle: advice, installation, calibration and service for high precision and low operating cost.